From Problem

to Solution

From Problem

to Solution

From Problem to Solution:

Innovative Strategies to Common Technical and Development Challenges

Welcome to our Beauty Edition! We all know that feeling when we discover a raw material with great properties or a great story behind it, but struggle to unlock its full potential and feeling stuck when it comes to making it work.

That's why we've dedicated this edition to provide solutions for common technical and development challenges that arise in your daily work.

Our goal is to equip you with practical solutions that will enable you to overcome these obstacles with ease. We appreciate your questions and are eager to assist you in navigating the complexities of your projects.

Get ready to discover effective solutions and bring out the best in every aspect of your work.

More foam please...

Foaming is a key factor in creating a satisfying user experience, as it is associated with the perception of cleaning and the effectiveness of the product. However, it is not uncommon to encounter challenges during the development process, such as insufficient foam or poor foam quality.

This can negatively impact consumer perception of the product's effectiveness and may ultimately result in reduced sales.

As a result, cosmetic developers must find effective solutions to overcome these challenges and deliver products that meet consumer expectations. See below several options that can be employed to address the foaming issues encountered during the development of rinse-off products.

1) Amilite™ ACS-12*

Amilite™ ACS-12 is a mild anionic surfactant derived from the amino acid L-Alanine.

This ingredient boasts impressive foaming capabilities, generating a rich and long-lasting lather, even in the presence of oils. In addition, it has the ability to significantly enhance foam volume, effectively boosting the performance of surfactants such as Sodium Laureth Sulfate (SLES) and Cocamidopropyl Betaine (CAPB), while keeping skin and hair moisturized.

Being 100% natural and COSMOS, Natrue certified, Amilite™ ACS-12 is an environment-friendly solution for natural sulfate-free product applications, optimally between pH 6 and 8.

*only available for our customers in: AT, CH, DE, IE and UK

Recommended use level: 5 - 30%

INCI: Sodium Cocoyl Alaninate

Guide Formulation Booklet: click here

Guide Formulation: Self-foaming Cushion Feel Cleanser & Makeup Remover

Product Presentation: click here

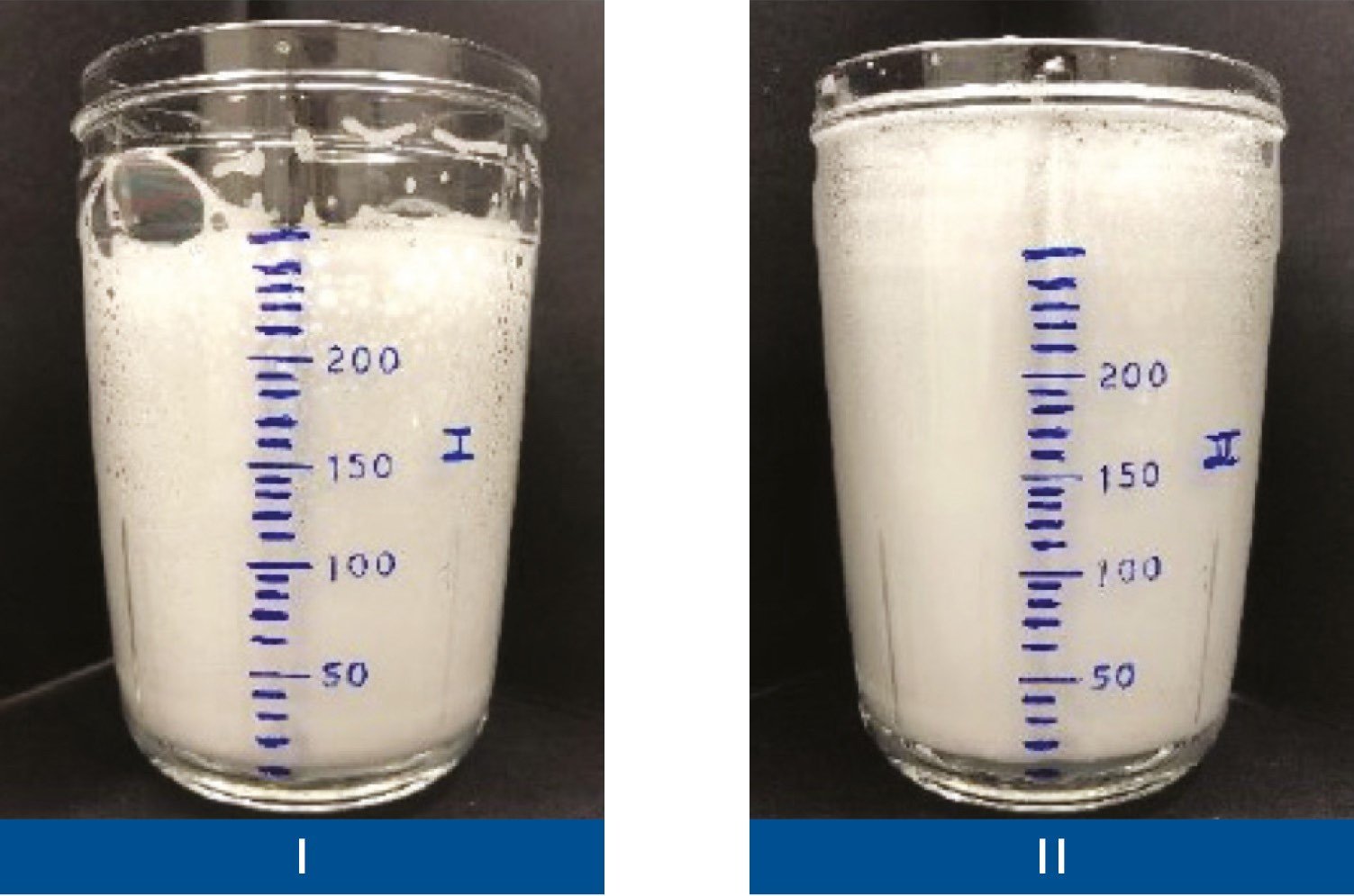

Amilite™ ACS-12 is added to a CAPB solution (II) compared to the solution with only CAPB (I)

Amilite™ ACS-12 is added to a CAPB solution (II) compared to the solution with only CAPB (I)

(It should be noted that this solution may not be suitable for products that contain quaternary ammonium compounds (quats)).

*only available for our customers in: AT, CH and DE

Recommended use level: 0.1%

INCI: Xanthan Gum

Presentation "This foam is a dream": click here

2) Keltrol CG-SFT*

When utilized at the appropriate concentration, Xanthan Gum (Keltrol CG-SFT) can significantly enhance the foam properties of a product. Its ability to boost foam is attributed to the formation of a network that reinforces and improves the quality of the foam (from left to right):

- 5% Amisoft ECS-22W and 95% demineralized water

- + 0.1% xanthan: excellent volume & creaminess

- + 0.2% xanthan: foam becomes brittle and produces larger bubbles

3) Amisafe® LL-DS-22*

AMISAFE® LL-DS-22 is an amino acid-based texture modifier derived from L-Lysine, Lauric acid, and Sebacic acid. The uniqueness originated from its Gemini-type surfactant chemical structure and properties as a hydrogelator.

In foaming cleansing products, it functions as a foam booster and imparts characteristic silky smoothness to dry skin and hair. AMISAFE® LL-DS-22 is a 100% natural ingredient.

By regulating the pH level, the AMISAFE® LL-DS-22 molecules are able to form a network of fibres that enhance the foaming properties of a product. This network structure provides stability to air bubbles, resulting in an increase in foam volume.

*only available for our customers in: AT, CH, DE, IE and UK

Recommended use level: 0.5 - 1.0%

INCI: Disodium Sebacoyl Bis-Lauramidolysine

Presentation "This foam is a dream": click here

Product presentation: click here

Surfactant thickening…transparent and natural?

The process of thickening a surfactant product can be a complex task, with no universal solution that can be applied across the board. The choice of surfactant, the pH levels, and other ingredients all play a crucial role and can often interfere with one another, making it difficult to achieve the desired results. Furthermore, complying with certain natural or industry regulations can add to the complexity of the process.

Meet GENUVISCO® carrageenan CG-129*, which is a lambda carrageenan and produced via extraction from red seaweed. It is an anionic water-soluble biopolymer, that thickens aqueous solutions and is stable under alkaline conditions. GENUVISCO® carrageenan CG-129 offers an excellent solution to the challenges of thickening surfactant products, as it is effective regardless of the type of surfactant used, resulting in a smooth and flowable highly transparent final product.

*only available for our customers in: AT, CH and DE

*only available for our customers in: AT, CH and DE

Recommended use level: 2 - 3%

INCI: Carrageenan

Guide formulation: Bee Sweet Honey Body Wash

Statement Surfactant Compability: click here

Solutions for Enzyme Performance

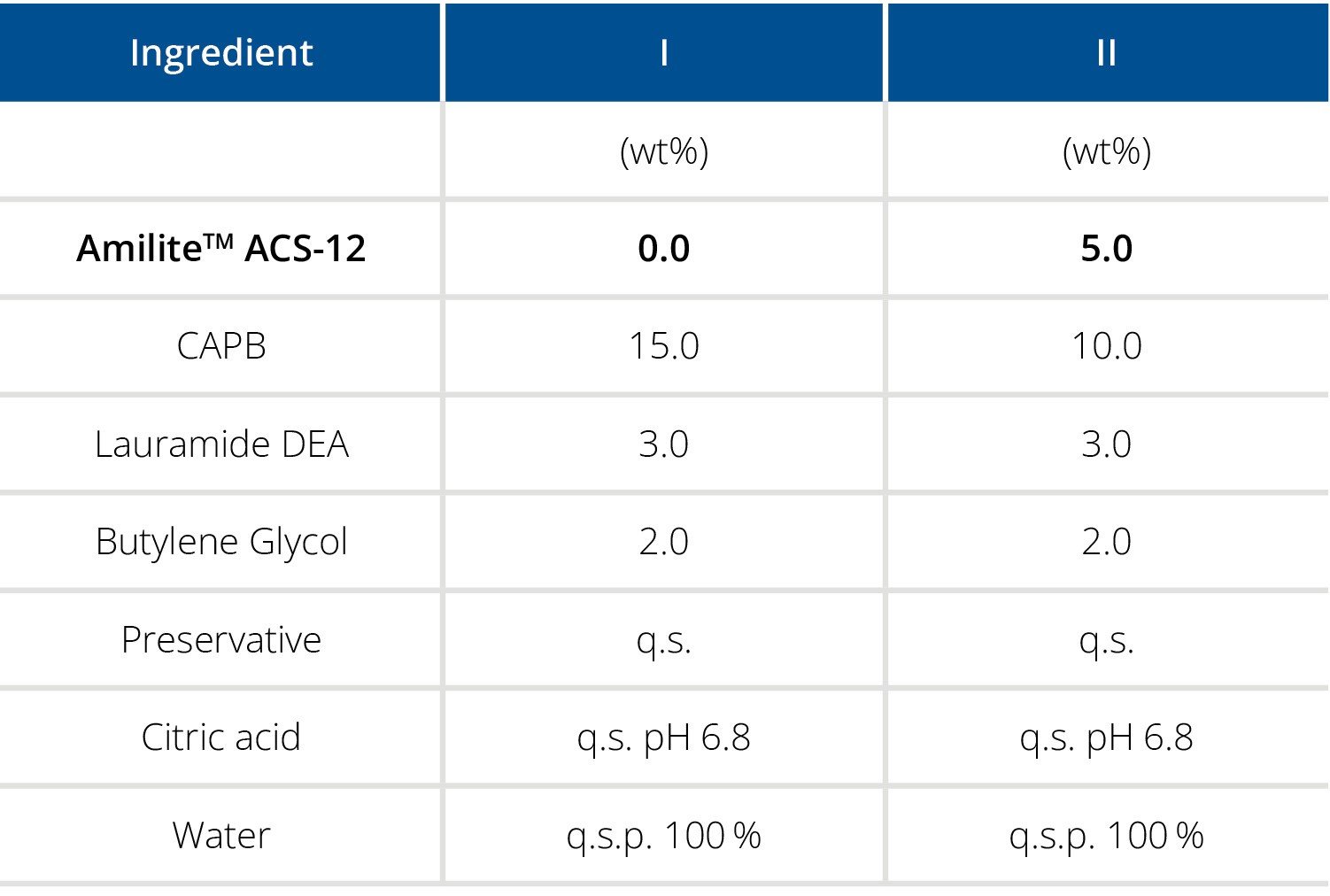

Maintaining the stability of enzymes in aqueous systems can be a challenging task. It is crucial to strike the right balance between stability and reactivity, ensuring that the enzyme remains stable while still maintaining its desired level of activity.

One effective approach to enhance the stability of enzymes in aqueous systems is to reduce the water activity using polyols such as glycerol or butylene glycol. Co-solvents like glycerol are often utilized in high concentrations to minimize water activity. However, it is important to note that enzyme activity requires a certain amount of water to maintain its conformation and maximum functionality.

Figure: Stability of Protease with high glycerol content

Take a look at our guide formulation Wash Cream Enzyme-Active.

Ceramides Challenge

Ceramides are incredibly powerful ingredients for the skin, strengthening the skin's natural protective lipid barrier, making them a strong skin energy activation instrument. However, the incorporation of ceramides into cosmetic formulations can pose a significant challenge, mainly due to the high processing temperatures involved in their production.

This often makes it difficult to achieve the desired result. Additionally, if ceramides are not processed correctly, they can recrystallize, leading to an inhomogeneous cosmetic product and ultimately affecting its overall quality.

For formulators seeking to incorporate the skin barrier-related benefits of ceramides into their formulations, Ceramide III EP MB* offers an easy-to-process solution. This product is available in pellet form and allows for processing at a low temperature of 75°C, significantly simplifying the manufacturing process.

Recommended use level: 0.05 – 0.5%

INCI: Ceramide NP

*only available for our customers in: AT and CH

*only available for our customers in: AT and CH

Guide Formulation: How to Formulate Ceramides

Product Presentation: click here

Product Presentation Technology: click here

*only available for our customers in: AT, CH, DE, IE and UK

*only available for our customers in: AT, CH, DE, IE and UK

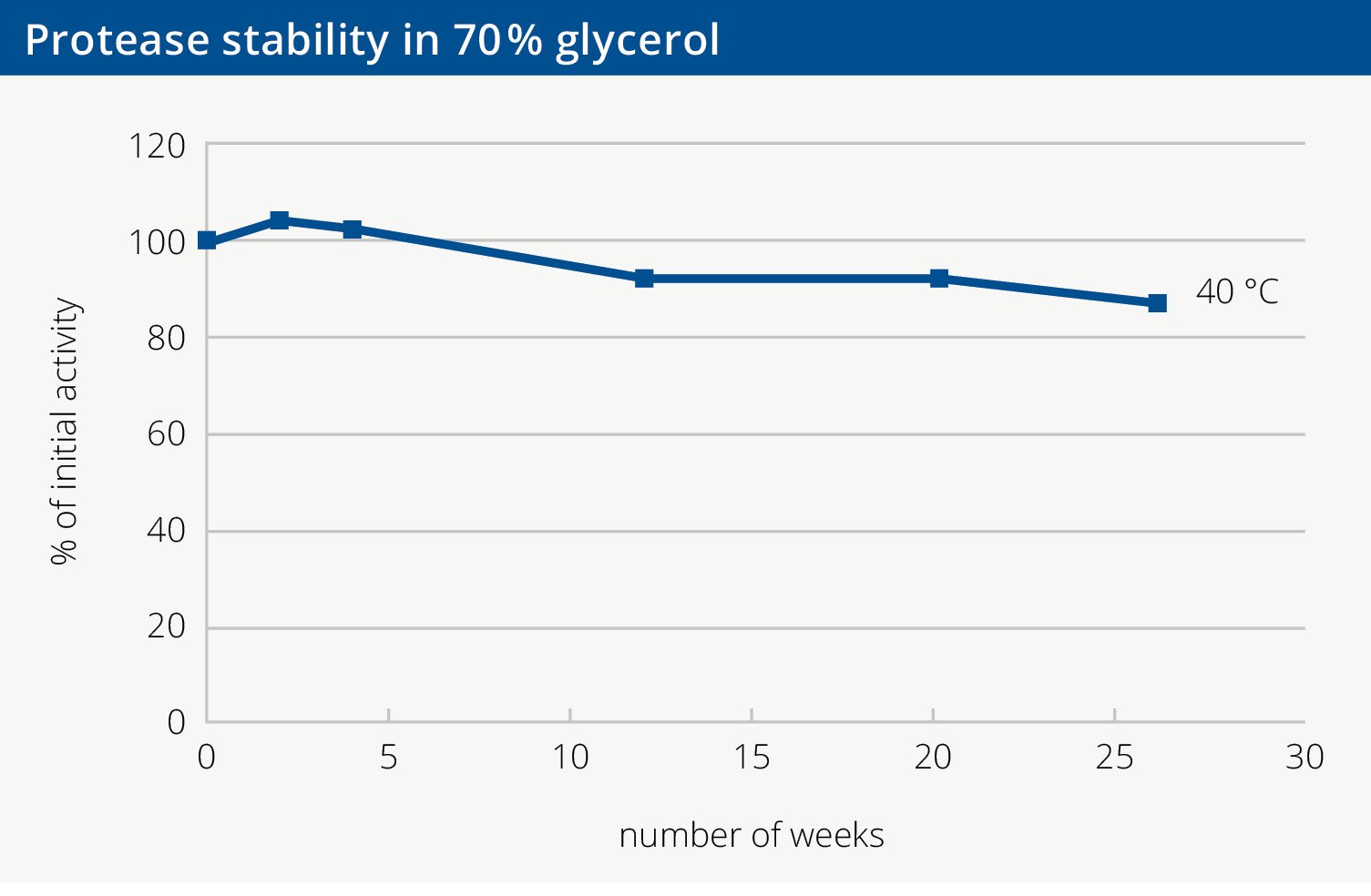

ELDEW® SL-205* is an amino acid derived highly polar emollient. One of the key advantages is its remarkable ability to dissolve functional ingredients, such as ceramides, with ease, allowing for their effortless incorporation into formulations, which in turn helps to enhance product stability. Additionally, this product provides a smooth and light skin feel, making it a highly desirable ingredient.

Recommended use level: 5 - 10%

INCI: Isopropyl Lauroyl Sarcosinate

Product Presentation: click here

Uniform distribution of pigments and UV filters

Achieving a consistent distribution of pigments or UV filters in cosmetic formulations can be a common issue due to their agglomeration challenges, which may lead to unevenness and loss of activity. The key objective is to attain a uniform distribution of those components to optimize the product's performance.

Prodew™ 700* comprises a combination of amino acid-based ingredients, including Zinc PCA and a blend of amino acids that closely resemble the skin's Natural Moisturizing Factor. This blend works deeply to nourish the Stratum Corneum.

Moreover, due to its excellent pigment dispersion properties, Prodew™ 700 can help to distribute pigments evenly throughout the formulation, leading to improved coverage and better UV protection. This makes it an ideal ingredient for creating emulsions with higher SPF ratings and make-up formulations while ensuring a smooth, even application on the skin.

Prodew™ 700 is a 50% aq. solution, easily incorporated in emulsions.

*only available for our customers in: AT, CH, DE, IE and UK

*only available for our customers in: AT, CH, DE, IE and UK

Recommended use level: 1 - 2%

INCI: Sodium PCA, Sodium Polyaspartate, Butylene Glycol, Betaine, Zinc PCA, Sodium Citrate, Arginine, Serine, Lysine HCl, Glutamic Acid, Water

Presentation "Enhancement of Sun Screening Effect": click here

Product Presentation: click here

Bakuchiol, Babchi oil and Bakuchi oil… What ‘s the real deal?

Sytenol® A* may ring a bell to you. It features Bakuchiol, a naturally sourced ingredient that has gained attention as a milder alternative to retinol. With comparable benefits but without the potential for skin irritation, Bakuchiol in Sytenol® A offers a compelling option for skincare enthusiasts (it is an important component of the weekly skin cycling routine). Are you aware that there are various products available, such as Babchi oil or Bakuchi oil, that make similar claims regarding their purity and properties? This can lead to confusion and potentially misleading information when attempting to select "the real deal".

The difference between babchi oil and Bakuchiol is the method of extraction. Babchi oil is produced by cold pressing the babchi seeds, just like other seed oils. Babchi oil does contain Bakuchiol, but in order to isolate the pure chemical, a different chemical process is needed. It is obtained through a monomolecular extraction from the Babchi seeds, which means there is only a one extract molecule.

Once babchi seeds are cold pressed, you have Psoralea corylifolia seed oil. If the seeds or leaves are macerated in oil or extracted with a solvent (i.e. ethanol), you have Psoralea corylifolia seed / leaf extract. Again, these might be referred to as babchi oil or bakuchi oil, but they represent an unrefined carrier oil and not the pure chemical form of Bakuchiol that is sought after.

According to one study that analyzed babchi seed carrier oils, these extracts will contain some Bakuchiol (1.6% – 12%). However, there is no standardization. This means there could also be irritating or undesired chemicals, like psoralens, which can be harmful to the skin in high concentrations. If you buy and use products containing babchi seed oil or bakuchi oil, you have no way to know how much Bakuchiol is present or what other chemicals are. There is no requirement for the brand to disclose this to you.

*only available for our customers in: AT, CH, FR and UK

*only available for our customers in: AT, CH, FR and UK

Presentation "Retinol to Bakuchiol": click here

Technical Information "Sytenol A vs generic Bakuchi extract": click here

Product Presentation: click here

Bakuchiol and Water Solubility?

A question we are often asked is whether Bakuchiol is soluble in aqueous systems. The quick answer is no, as Bakuchiol is an oily component. You can find our solution below.

Symbio® solv clear plus MB

Incorporating Sytenol® A into a watery solution, such as a face tonic, can be challenging as it may result in a non-transparent solution. Although Polysorbate 20 can be used to address this issue, it is not widely accepted in Europe due to its non-natural ethoxylated (PEG) nature. However, through laboratory trials with more natural solubilizers, we have discovered a solution that enables the achievement of a clear, transparent Sytenol® A solution without PEG, which is also Natrue approved.

Symbio® solv clear plus MB* can facilitate the attainment of a transparent solution with excellent solubilization and color performance for Sytenol® A (see figure below). However, a high usage level of Symbio® solv clear plus MB is required to achieve this outcome. In our testing, a dosage of approximately 6.6% of Symbio® solv clear plus MB was necessary to solubilize 0.3% Sytenol® A.

Recommended use level: 5 - 8%

INCI: Caprylyl/Capryl Glucoside, Aqua, Sodium Cocoyl Glutamate, Glyceryl Caprylate, Citric Acid, Polyglyceryl-6 Oleate, Sodium Surfactin

Sample 3a highlights the superior Sytenol A solubilization performance of Symbiosolv Clear Plus in comparison to other solubilizing agents.

*only available for our customers in: AT and CH

Marketing Leaflet Symbio® solv clear plus MB: click here

Product Presentation Symbio® solv clear plus MB: click here

Product Presentation Sytenol® A: click here

Your personal contact

Sandra Gut

Senior Application Laboratory Manager Cosmetics

RAHN (UK) Ltd.