How can different droplet sizes

impact my emulsion?

How can different droplet sizes

impact my emulsion?

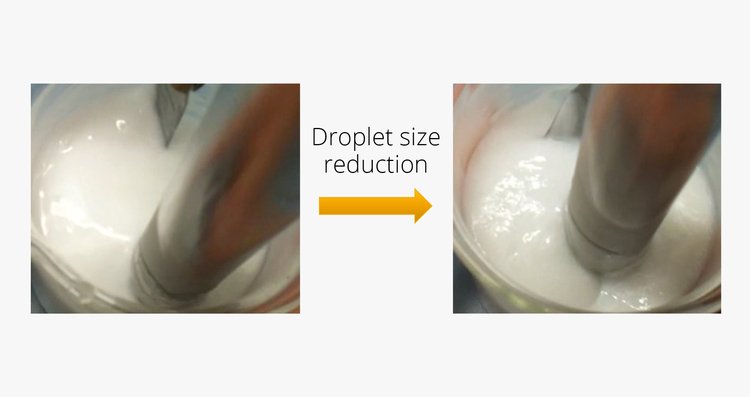

The size of droplets can play an important role when it comes to texture and stability of an emulsion. Especially during the scalling-up of laboratory batches for production, different droplet sizes often occur.

The cause for this "oil migration" is actually a space problem. In such cases the oil phase does not have enough space and is therefore (at least partially) pushed out of the system.

If the internal phase of the production batch is dispersed more finely (=smaller droplets), there is a risk of an increase in viscosity. A bodylotion for example could turn into a cream or even a butter-Iike consistency. In this case it is aIso very difficuIt to apply the product on the finger.

The following situations are relevant to consider:

- The internal phase has reached an unfavourable size (too large) in relation to the external phase.

- Gelling agents in the external phase bind a lot of space due to their swelling behaviour

- The smaller the droplets in the internal phase are, the more space is taken up

What can trigger such an oil migration in an O/W emulsion?

- A strong gel network exists in the water phase (like carbomers, xanthan gum, etc.)

- The oil phase is relatively large and therefore demands a certain amount of space within the emulsion.

- The finer the droplets become, the more space the oil phase requires.

How can I solve the problem?

- Exact control of droplet size during production

- Reduction of oil phase size (internal phase)

- Reduction of hydrocolloids (external phase)

- Change of HLB value or emulsifier ratio to avoid a lamellar structure formation

Your personal contact

Sandra Gut

Senior Application Laboratory Manager Cosmetics

RAHN (UK) Ltd.